Dry Electrostatic Precipitator

Electrostatic precipitators have become an indispensable choice for eliminating dust from industrial flue gas due to their technical characteristics and wide range of applications. They offer significant advantages in terms of energy consumption, maintenance, and the cost of spare parts. Moreover, the lifespan of an electrostatic precipitator typically exceeds that of upstream production equipment such as rotary kilns, mills, dryers, and coolers.

Electrostatic precipitators have become an indispensable choice for eliminating dust from industrial flue gas due to their technical characteristics and wide range of applications. They offer significant advantages in terms of energy consumption, maintenance, and the cost of spare parts. Moreover, the lifespan of an electrostatic precipitator typically exceeds that of upstream production equipment such as rotary kilns, mills, dryers, and coolers.

ELEX electrostatic precipitators are capable of reducing dust concentrations exceeding 100g/Nm³ to residual levels that meet ultra-low emission standards. Since 1934, we have installed over 7,000 electrostatic precipitators for customers worldwide, a testament to the high efficiency and durability of our products. All components of our electrostatic precipitators utilize the most advanced technologies from our company, ensuring continuous improvement and development in the overall equipment quality. Additionally, the measurement and analysis of operating parameters under various conditions have provided us with rich technical experience. By choosing ELEX equipment, customers will greatly benefit from our unique core technologies.

► Advantages of MUWELT-ELEX Electrostatic Precipitators

MUWELT-ELEX electrostatic precipitators, through relentless innovation and refinement, have rightfully become the preferred choice for customers.

► Low Emission, High Efficiency Electrostatic Precipitator

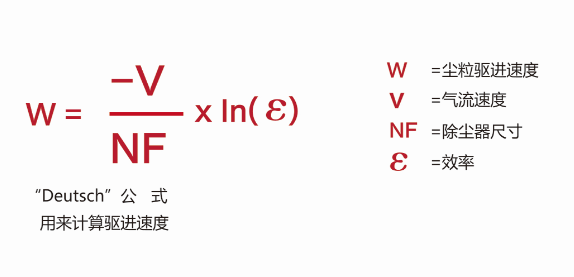

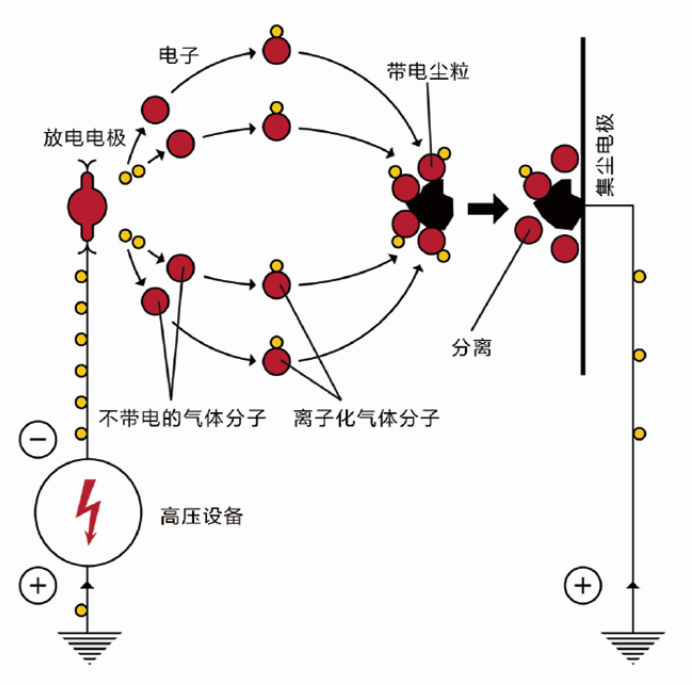

Electrons are released from the negatively charged discharge electrode, which is supplied with high-voltage rectified current, and move toward the positively charged collection electrode. When electrons deposit onto the surface of dust particles, the particles become negatively charged. The electric field then transports these charged particles to the collection electrode, where they are collected.

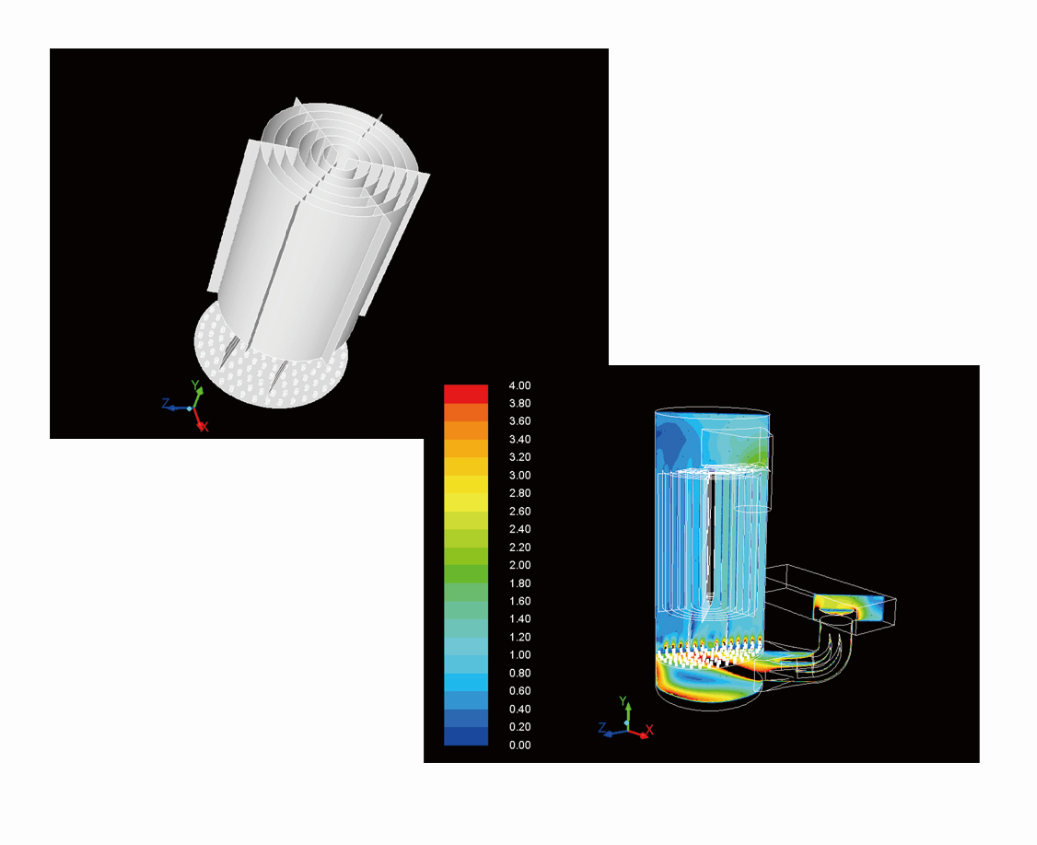

In ELEX electrostatic precipitators, the collection electrodes are composed of specially shaped metal plates. These plates form a channel system through which the exhaust gas flows. The highly efficient ELEX RS-type discharge electrodes are distributed along the central axis of the 400 mm wide channels. Mechanical rapping devices periodically clean the collection electrodes through timed rapping. The highly efficient RS electrodes and the maintenance-friendly design are two key features of ELEX electrostatic precipitators。

► Advanced Electrical Control System Ensures Safety and Trouble-Free Operation

To meet the high demands of our customers, we not only use high-quality components but also implement strict control and management during equipment installation. Our precise theoretical knowledge of optimal sizing is a key factor in ensuring cost stability. Our electrical control system, governed by microprocessors, features sophisticated hardware and software facilities, along with accurate signal value recording. This is complemented by a full set of automatic and manual control devices, ensuring the safe and reliable operation of the equipment.

► Successful Cases Demonstrate the Advanced Nature of ELEX Electrostatic Precipitators

- ELEX has numerous cases where dry electrostatic precipitators alone achieved emissions as low as 10 mg/Nm³.

- The RS electrode, invented by ELEX, is now used in over 70% of applications worldwide.

- More than 7,000 highly acclaimed installations.

- Successful applications in specialized fields such as high-temperature and explosive environments.