Bag filter and electrostatic-bag composite filter

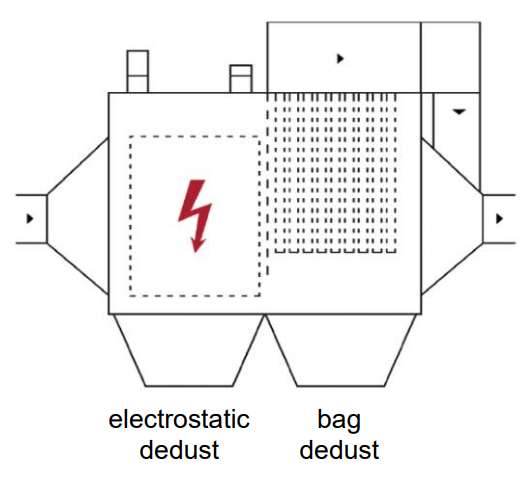

The baghouse dust collector represents one of the most traditional dust removal technologies, utilizing filtration through filter materials/bags to intercept and remove dust from flue gas. On the other hand, the hybrid electrostatic-fabric integrated dust collector combines a maintenance-free electrostatic precipitator with a baghouse dust collector, leveraging their synergistic effects to achieve ultra-low dust emissions with minimal energy consumption.

The customized hybrid electrostatic-fabric integrated dust collector system by MUWELT embodies decades of rich experience and relentless efforts from ELEX.

The hybrid electrostatic-fabric integrated dust collector enhances the efficiency of existing equipment. Typically, when operational conditions change or production capacity expands, existing dust collection equipment may no longer meet the requirements. In such cases, instead of replacing the entire system, an electrostatic precipitator can be upgraded to a hybrid electrostatic-fabric integrated dust collector to adapt to the new environment.

The advantages compared to traditional baghouse dust collectors are as follows:

The front-end electrostatic dust removal stage boasts high efficiency, collecting at least 90% of the dust with very low energy consumption. Due to the ionization and agglomeration effects of the electrostatic dust removal process, the pressure loss in the back-end baghouse dust removal equipment is reduced by up to 40%. Since only 10% of the purification function is carried out by the baghouse dust removal stage, the consumption of compressed air is significantly reduced, which greatly extends the service life of the filter bags and the maintenance intervals. Consequently, the overall efficiency is also higher than that of using a baghouse dust collector alone.