Wet Electrostatic Precipitator

Wet electrostatic precipitators (WESPs) are highly efficient air pollution control devices designed for the advanced treatment of atmospheric pollutants. They are capable of capturing over 90% of both micron-sized (1.0 to 5.0 μm) and submicron-sized (<1.0 μm) particulate matter. As such, WESPs are highly effective in controlling PM2.5 pollution and mitigating haze conditions.

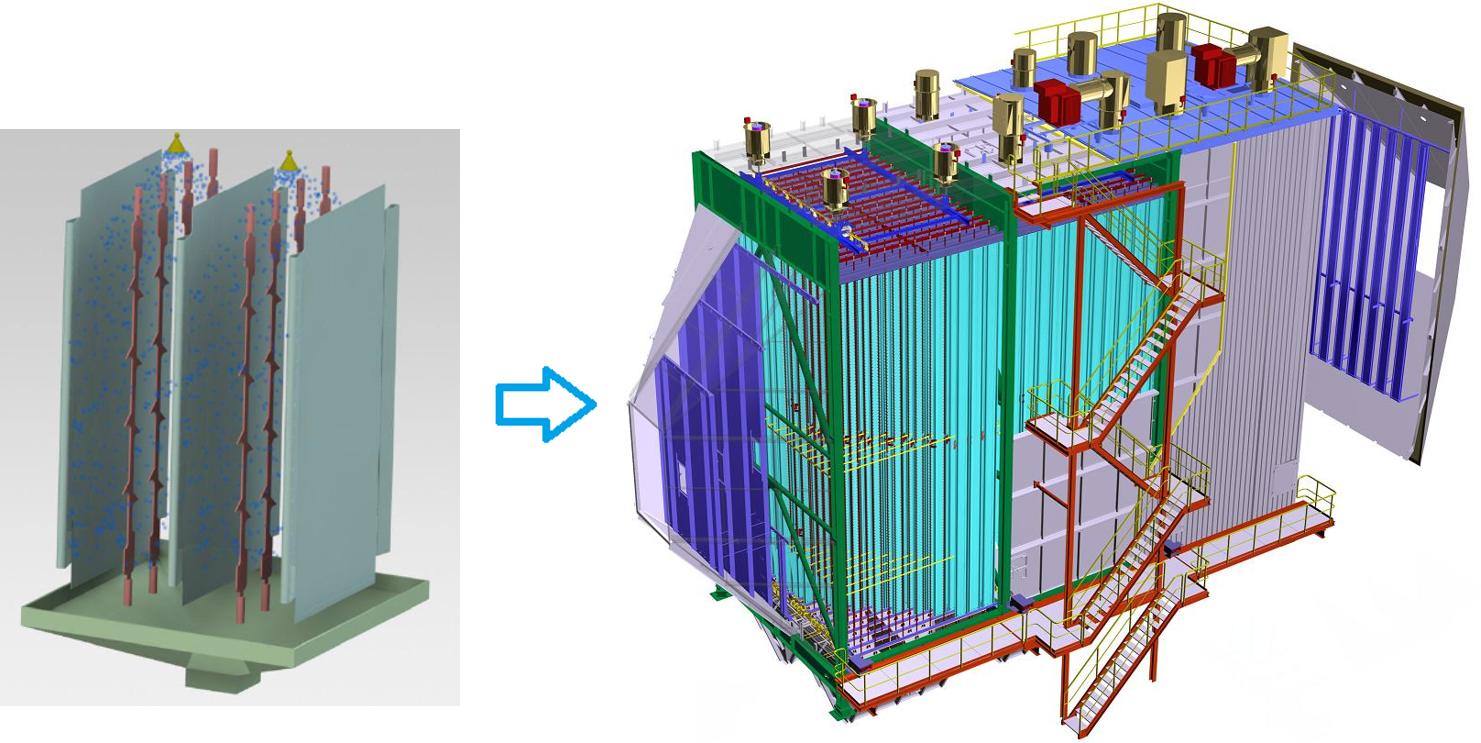

Working Principle:

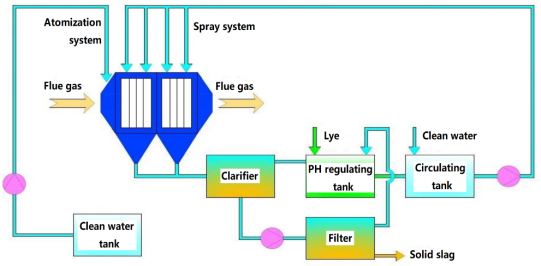

Flue gas containing dust particles enters the wet electrostatic precipitator, where it first encounters a spray system at the inlet section. This system thoroughly mixes atomized water vapor with the flue gas. The mist droplets and dust particles then acquire a negative charge as they pass through the ionization zone. Driven by the electrostatic field, these charged particles migrate toward the positively charged collection plates, where they adhere to the surface. The collected particles are periodically removed by washing the plates.

Advantages of MUWELT-ELEX Wet Electrostatic Precipitator

Building on the excellence of dry electrostatic precipitators, our wet electrostatic precipitator not only retains the advantages of dry electrostatic precipitators, such as exceptional efficiency, optimized design details, excellent reliability, and operational efficiency, but also incorporates a unique "continuous atomization, intermittent spraying" technology. This makes our wet electrostatic precipitator highly adaptable and capable of effectively removing complex and difficult-to-capture particles. Specifically:

► It achieves very high capture efficiency for fine solid particles and liquid droplets, making it particularly suitable for dust that conventional electrostatic precipitators and bag filters cannot capture.

► It allows for higher design flow rates, resulting in a more compact equipment size and reduced construction costs.

► It utilizes hydraulic cleaning, eliminating the need for mechanical rapping systems and avoiding secondary dust entrainment.

► It also provides some removal of other pollutants in the flue gas, such as SO3, mercury, and heavy metals.

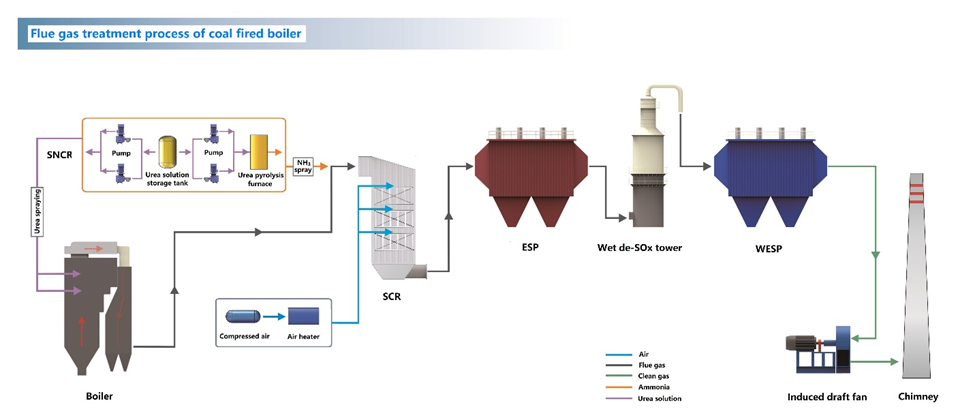

► It has a wide range of applications, including thermal power generation, sulfuric acid production, smelting, steel manufacturing, and various other industries.

The process flow of wet electrostatic precipitator

Purification Efficiency of Wet Electrostatic Precipitators for Industrial Flue Gas:

► Dust removal rate: 98%, with outlet dust content <5 mg/Nm³, or even lower

► HCl removal rate: 60%

► C removal rate: 99%

► Cd removal rate: 60%

► SOx removal rate: 90%

► HF removal rate: 50%

► Pb+Zn removal rate: 94%

► Hg removal rate: 60%