MUWELT, Alles für Umwelt!

MUWELT, All for the environment!

珍爱地球 · 保护环境 · 合理开发

Cherish the earth and protect the environment and rational development

绿水青山就是金山银山

Lucid waters and lush mountains are invaluable assets

江苏沐唯特环保科技有限公司MUWELT Environmental Technology Co., Ltd.

-

-

Denitrification

除尘设备是利用拦截过滤或者静电吸附等原理去除烟气中的细微颗粒物的设备。公司能够为客户提供各种除尘设备,尤其是技术来自于瑞士ELEX的静电除尘器有着卓越的设计和先进的性能。ELEX静电除尘器在全球有超过7000套应用案例,深得客户的信赖与好评。

The most common denitrification technologies include SNCR without catalysts and SCR with catalysts, both of which use ammonia as a reducing agent to convert NOx into nitrogen gas and water, thereby completely rendering NOx harmless. SNCR has poor temperature adaptability and needs to be used at temperatures above 900 ℃. SCR can react within the range of 180 to 400 ℃, with high denitrification efficiency, low ammonia escape, and simple equipment maintenance and operation. The SCR has become the mainstream process in the denitrification market.

Since 1988, ELEX has been providing equipment for catalytic flue gas purification projects. This purification process removes toxic substances such as nitrogen oxides, dioxins, furans, hydrocarbons, and ammonia, without generating secondary pollution, and can meet the world's strictest emission standards. Since the first ELEX device was put into operation, our technology has been proven to be completely effective. Thanks to relentless research, we are able to continuously improve our system and expand infinite possibilities. Our products are spread all over the world and are known for their efficient operation, which once again proves the reliability of ELEX technology and services.

Advantages of Muweite LEX Denitrification Reactor

We are your trusted partner because we not only provide one-stop turnkey services, but also offer specialized project renovation services according to customer requirements.

>> Flexible customized and optimized solutions for different working conditions

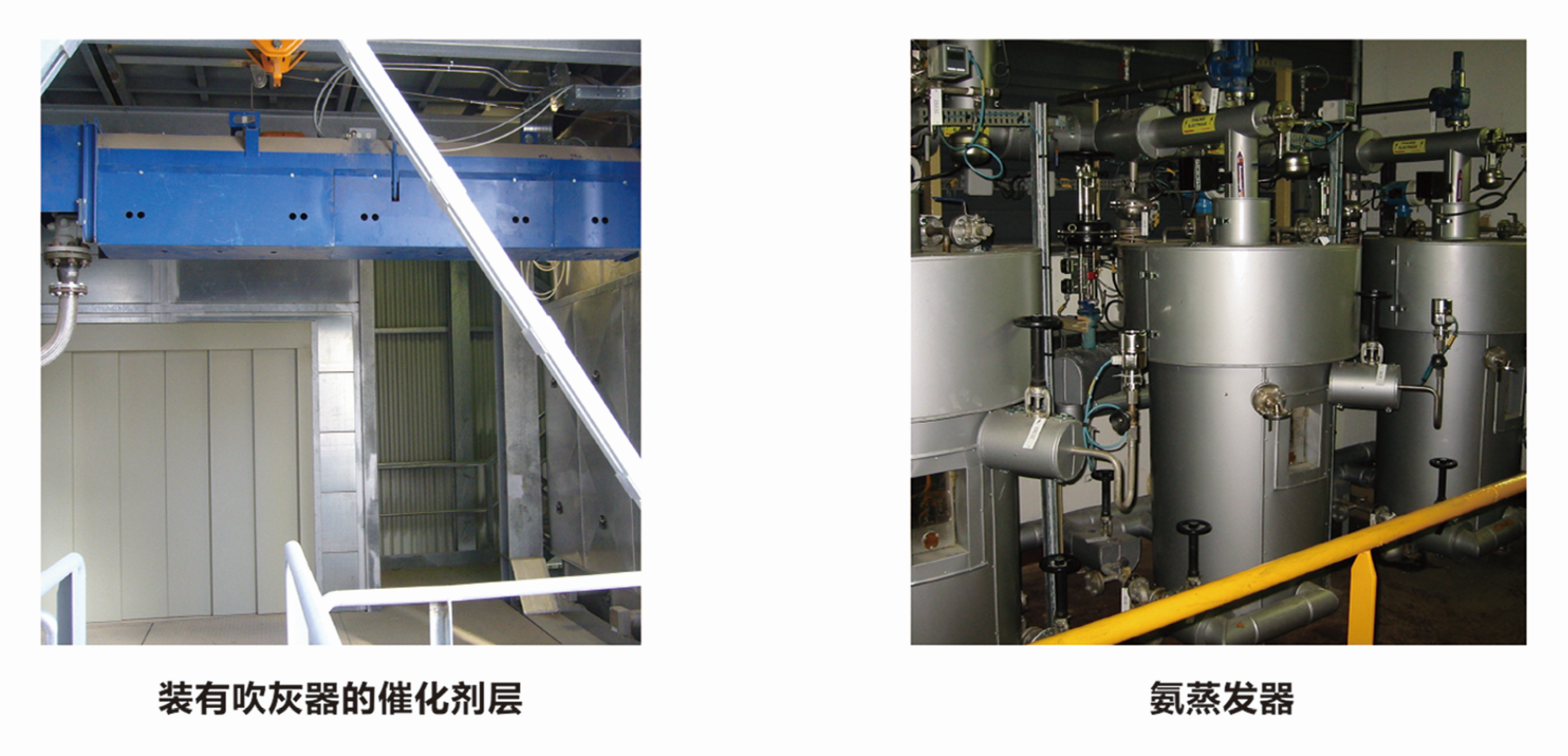

ELEX collaborates closely with leading catalyst manufacturers both domestically and internationally to develop specialized catalytic systems for various fields. For example, in response to the heterogeneity of waste incineration raw materials and the complexity of exhaust gas, as well as the high dust and high temperature environment of cement denitrification, we have designed the best process routes and developed unique functional components, such as powerful and efficient rake blowers, which greatly reduce energy consumption while ensuring denitrification efficiency.

>> Excellent reliability and comprehensive ability to remove secondary pollutants

Choosing and trusting superior technological systems is a crucial factor. Another important factor is how to accurately apply system principles to engineering practice and solve each unique problem. ELEX effectively addresses these two points, making it an outstanding leader in the market with its outstanding performance and reliability.

Achieve optimal efficiency through optimized design

The amount of flue gas to be treated, nitrogen oxide concentration, purified flue gas emissions, and acceptable ammonia escape are decisive factors in designing an SCR device. But in garbage incineration, the oxidation process of dioxins and furans needs to be considered separately. In general, the amount of catalyst required for this reaction is greater than that for denitrification alone.

Details determine success or failure. The most important factors affecting the efficiency of SCR denitrification reaction tower are the mixing degree of ammonia injection and the degree of uniform distribution of gas flow on the catalyst surface. We have strong computer-aided design and simulation capabilities, which fully ensure that the design of every equipment and flue is optimized. At the same time, we have practiced and verified in rich engineering cases, achieving excellent process level and technical quality of our products.

General operating data of SCR equipment

>Gas flow rate:5000 - 500000 Nm³/h

>Inlet NOx concentration:200 - 50000 mg/Nm³

>Outlet NOx concentration:20 - 100 mg/Nm³

>Ammonia escape:<3 mg/Nm³

>Dioxin/furan removal rate:up to 99%

>Reducing agents: ammonia water, liquid ammonia, and urea

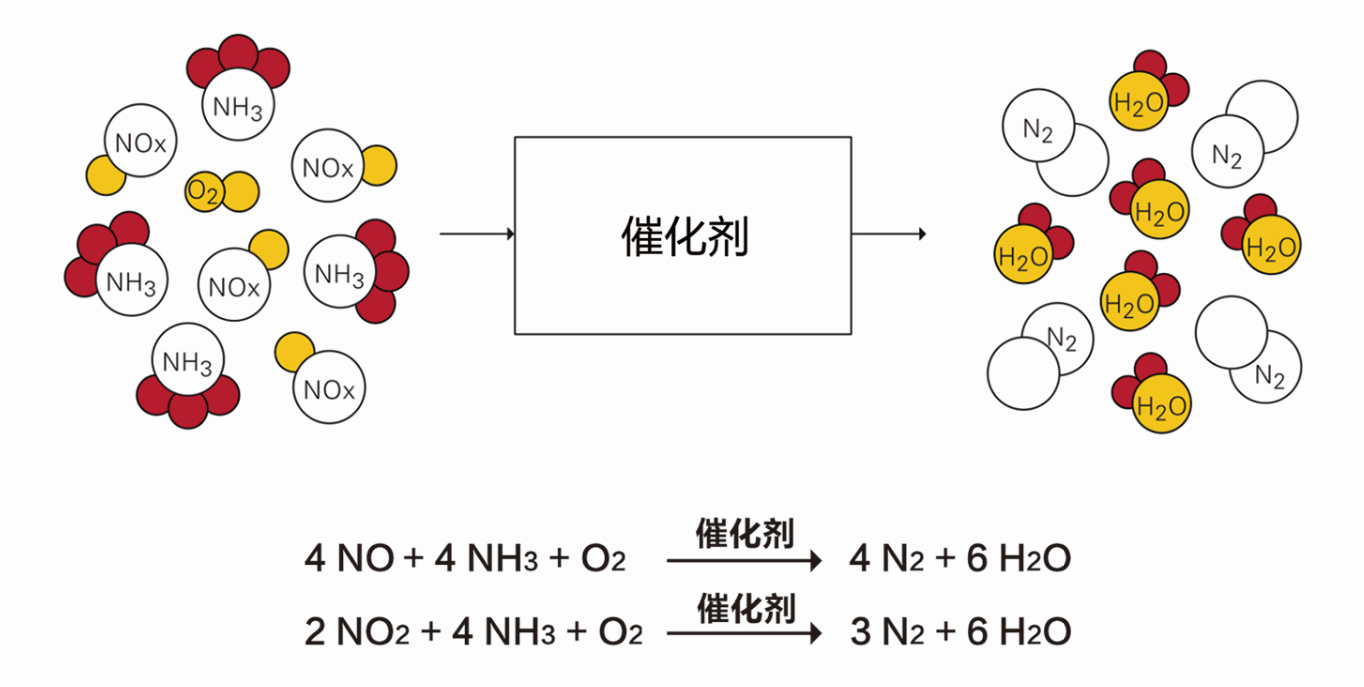

Principle of Denitrification:

Injecting ammonia (NH3) into the flue gas upstream of the SCR reactor, these three substances - nitrogen oxides (NOx), ammonia (NH3), and oxygen (O2) - react on the catalyst surface, where nitrogen oxides (NOx) are reduced to nitrogen (N2) and water (H2O).

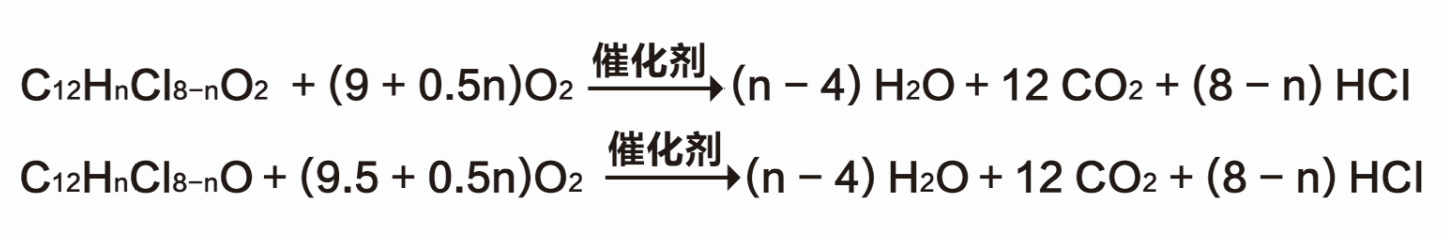

Removing dioxins and furans:

The main advantage of SCR system is that it can not only reduce nitrogen oxides, but also remove other pollutants in exhaust gas, such as dioxins and furans. In addition, this process not only destroys these harmful substances but also does not cause secondary pollution. In the SCR reaction, the oxidation of dioxins and furans occurs according to the following formula:

The oxidation of dioxins, furans, and hydrocarbons and the reduction of nitrogen oxides all occur at the same reaction temperature.

。