MUWELT, Alles für Umwelt!

MUWELT, All for the environment!

珍爱地球 · 保护环境 · 合理开发

Cherish the earth and protect the environment and rational development

绿水青山就是金山银山

Lucid waters and lush mountains are invaluable assets

江苏沐唯特环保科技有限公司MUWELT Environmental Technology Co., Ltd.

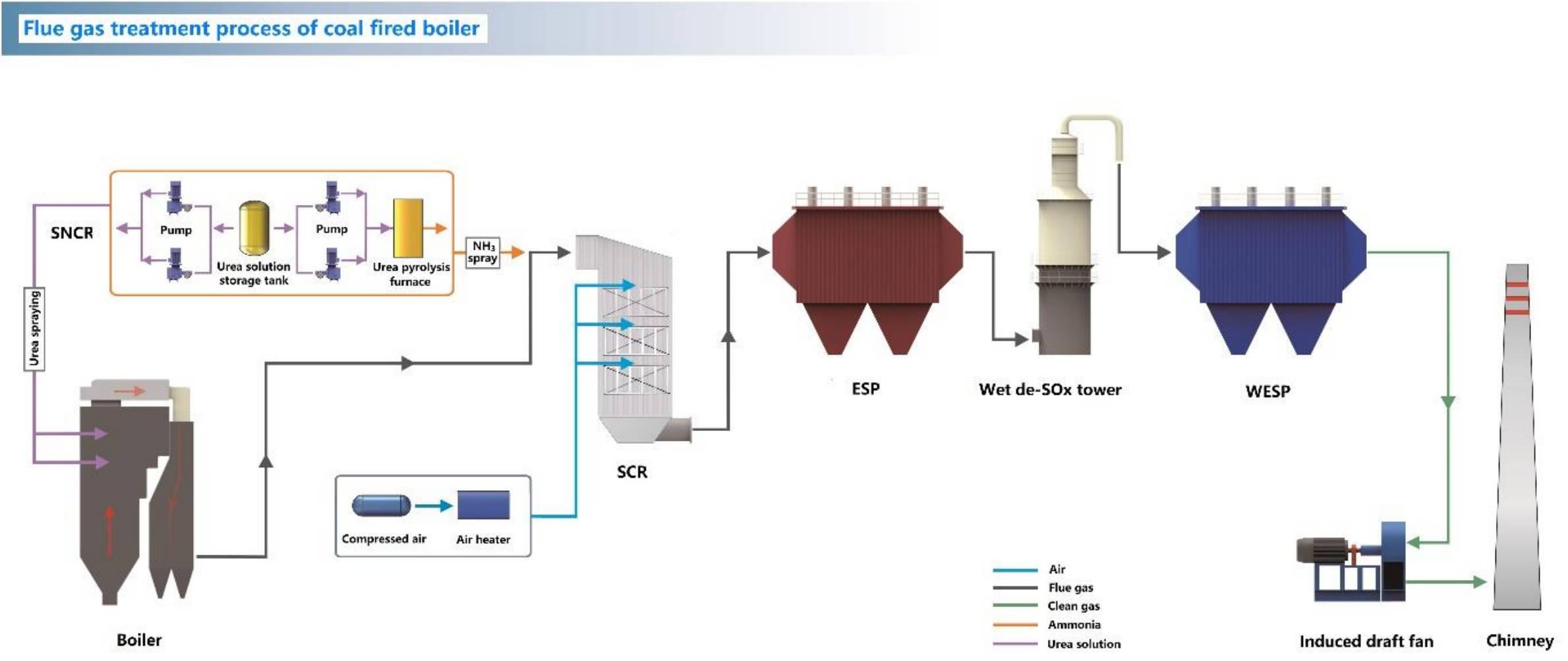

The most common arrangement for coal-fired boiler flue gas treatment is the SCR pre installation, which is a high-temperature and high dust arrangement. This is to arrange the SCR denitrification system in front of the economizer, with high denitrification temperature and good effect, and a more flexible downstream process layout. However, due to the high dust environment, it is necessary to use large-diameter catalysts and efficient ash cleaning systems, which have certain limitations in their application due to their large volume.

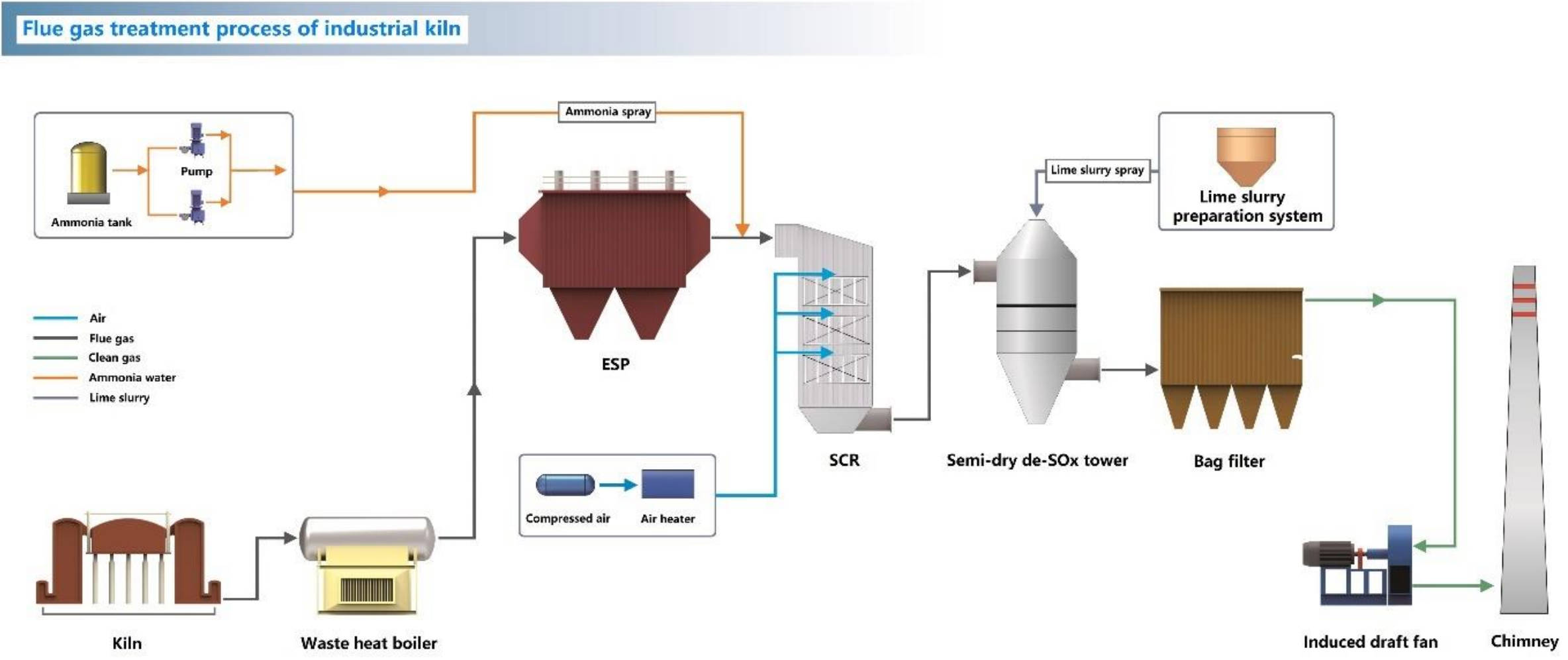

Most industrial kilns adopt a high-temperature and low dust layout with SCR post installation for flue gas treatment. After dust removal, the flue gas enters the SCR reactor for denitrification. Due to the low dust concentration and good denitrification temperature, small pore catalysts can be used. The catalyst has a small volume, high efficiency, is not easily poisoned, and has a long service life. The difficulty of this arrangement lies in the high-temperature electrostatic dust removal equipment in the front of the SCR denitrification tower. We have rich experience in high-temperature electrostatic dust removal and can provide customers with high-quality overall solutions for dust removal and denitrification.

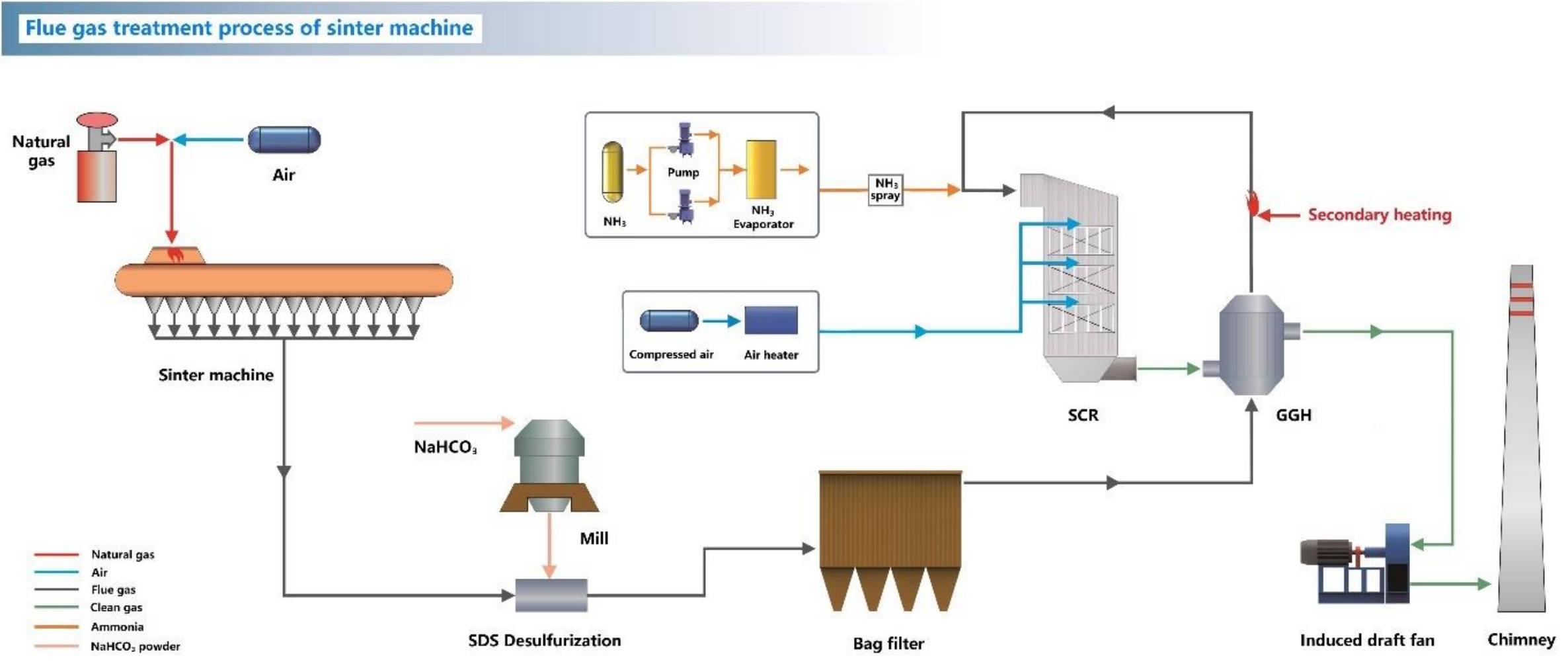

Sintering machine flue gas treatment has its particularity: the flue gas temperature is low, but the flow rate is very large, reaching millions of standard cubic meters per hour. The simplest approach is to heat exchange the inlet and outlet flue gas of the SCR denitrification tower after dry desulfurization and dust removal of all flue gas. The preheated flue gas is then reheated and enters the denitrification tower. This method is simple, reliable, and economically practical, but the disadvantage is that secondary heating of a large amount of flue gas will bring huge energy consumption. It requires comprehensive consideration of the enterprise's own energy production and usage situation to optimize the layout.

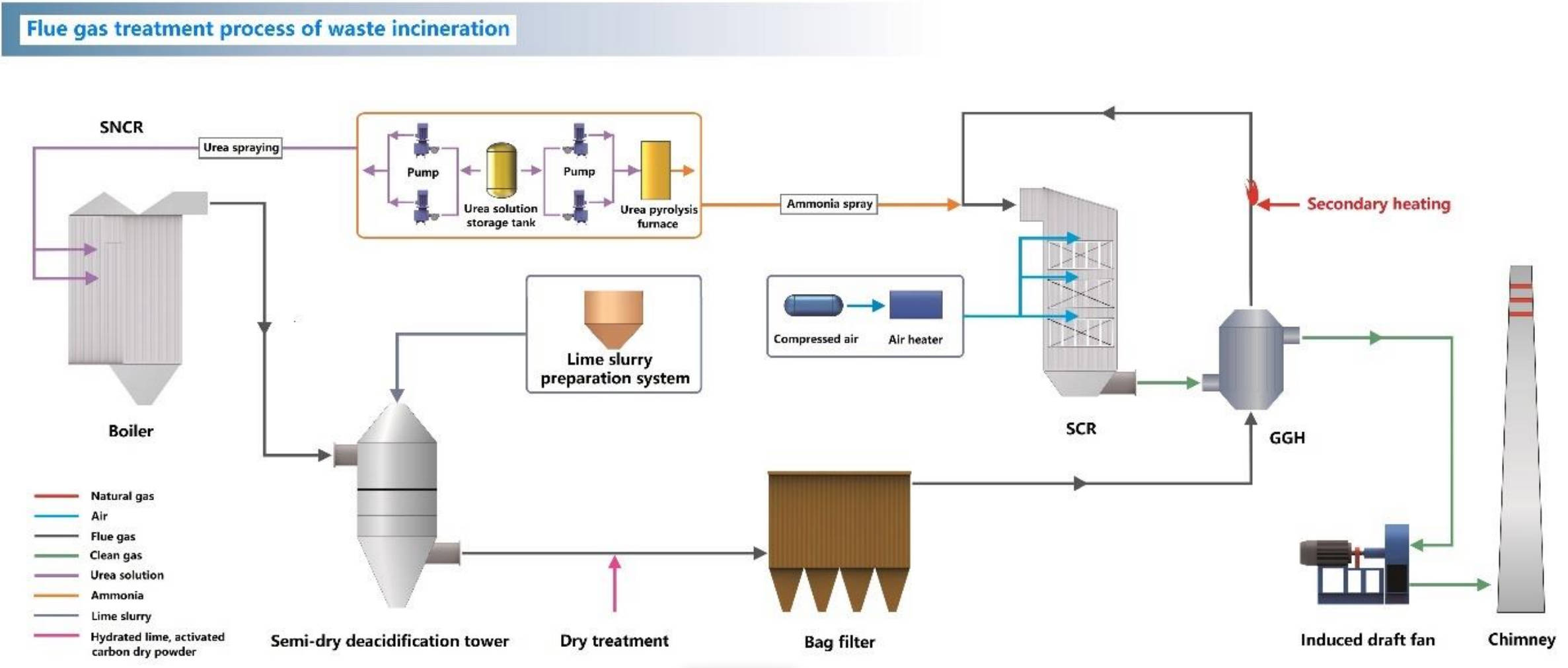

The flue gas treatment of garbage incineration in China mostly adopts the form of SCR denitrification placed at the end of the flue gas treatment process. This form is common in processes with complex flue gas components that require desulfurization before denitrification. Due to the lower temperature of the flue gas after desulfurization, denitrification requires the use of inlet and outlet flue gas self exchange and secondary heating to increase temperature, which will bring certain energy consumption. Due to the previous dust removal and desulfurization treatment, denitrification can achieve good results, and the suitable temperature for denitrification reaction can also be appropriately reduced.

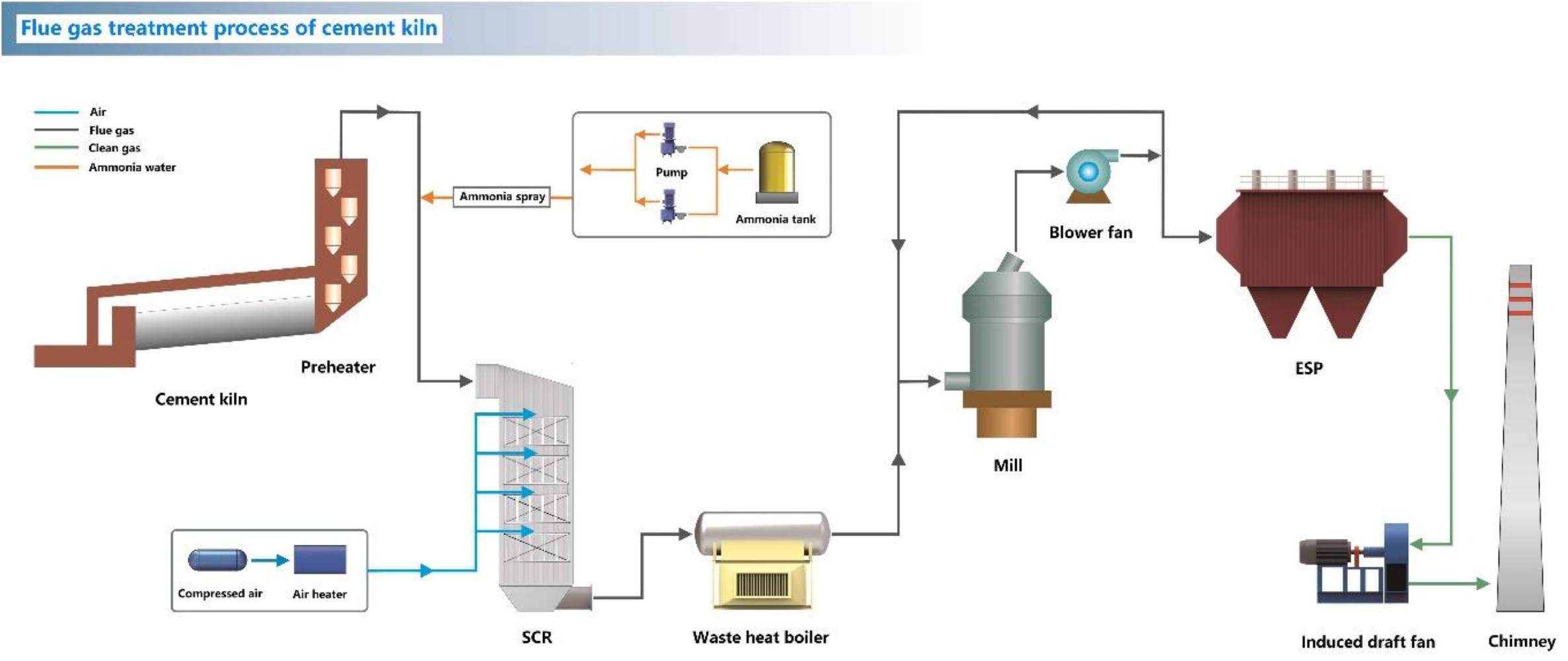

The flue gas from cement rotary kilns is different from other industries in that it has a high dust concentration of over 100 g/Nm3 and high viscosity. We have adopted a high dust SCR denitrification process, which can directly carry out denitrification in the high dust and high temperature area after the preheater. The emissions after denitrification can meet the requirements of ultra-low emissions (<50 mg/Nm3), and ammonia escape can be controlled below 3ppm. Due to the use of large-diameter catalysts, there are generally more catalyst layers in the SCR denitrification tower. Our advanced soot blowing system can ensure the cleanliness and efficiency of the catalyst, thus enabling the denitrification tower to operate stably for a long time. Compared to other processes, the cement flue gas high-temperature and high dust treatment process has the advantages of low emissions, low investment, and low operating costs.

The company's technical team tailors economic, efficient, and reliable process solutions for customers based on long-term engineering experience and analysis and understanding of the characteristics of various industries, combined with China's national conditions. Due to our comprehensive technology covering all aspects of flue gas treatment and deep understanding of technologies such as dust removal, desulfurization, and denitrification, our process design is more flexible, adaptable, and more cost-effective on the basis of efficiency and reliability.

At present, the process design of flue gas treatment mainly revolves around three main parts: dust removal, desulfurization, and denitrification. The process flow for removing VOCs and deodorization is relatively simple and independent. According to the different locations of SCR denitrification, it can be arranged in three forms: high temperature and high dust, high temperature and low dust, and low temperature and low dust. In practical engineering applications, it is necessary to comprehensively consider various factors based on the flue gas conditions and production process conditions, and specify the most reasonable and reliable process plan.

The following are several typical flue gas treatment processes in the industrial field.

典型工艺 / PROCESS FLOW